Agronomic strategies for managing water repellence on sandplain soils – research and grower experience in WA

Author: Stephen Davies, Paul Blackwell, Derk Bakker, David Hall and Craig Scanlan | Date: 22 Aug 2013

Keywords: soil water repellence, improved minimum-till furrow sowing, banded wetting agents, soil inversion, mouldboard ploughing, rotary spading

Take home messages:

- Start with the seeder – winged points or seeding boots, paired-row seeding systems, splitter boots, on-row seeding, or banded wetting agents can improve the effectiveness of minimum-till furrow sowing over knife points alone, particularly when seeding in dry or partially dry conditions.

- Improving the effectiveness of furrow sowing is less expensive, can be more cost effective in the short-term, involves less investment risk in poor seasons and is easy to test compared to the amelioration options.

- One-off deep cultivation techniques such as rotary spading or soil inversion using a mouldboard or square plough, without addition of clay-rich subsoil, can bury and dilute repellent topsoil resulting in medium-term amelioration. Crop yield improvements can be large but the techniques are expensive and the longevity of responses is still being determined. Deep cultivation also impacts weeds, pH profiles and nutrient distribution but needs to be implemented carefully to minimise wind erosion, seeding too deep and surface crusting risks.

- Soil mixing such as rotary spading often proves an excellent clay incorporation method and offers opportunities for simultaneous incorporation of soil improvers such as lime or gypsum.

Introduction

Nearly 3.3 M Ha of agricultural sandplain soils in WA are at high risk of soil water repellence with a further 6.9 M ha at moderate risk (van Gool et. al. 2008). Affected sandplain soils include pale deep sands, deep sandy earths that are sandy at the surface but have gradual increase in clay content with depth, sandy gravels, sandy duplex and loamy (forest) gravels. The severity or expression of soil water repellence in the form of poor crop establishment appears to be increasing and is likely to be partly a result of: reductions in the size and frequency of break-of-season rains; dry seeding; minimum (“Min-Till” methods including knife point or disc seeding systems) tillage resulting in higher topsoil organic matter content and stratification of organic matter near the soil surface; increased plant dry matter inputs from improved agronomic practices and greater adoption of knife point seeding systems.

The available options to manage soil water repellence fall into two broad categories:

1) The mitigation options aim to improve “Min-Till” crop establishment in the water repellent soil but do not remove the water repellent material. These strategies are typically relatively low cost (Table 1) however they need to be used each year because the water repellent material still remains. Options include:

- Add banded surfactant formulations to existing knife point or disc systems to retain maximum cover and not compromise erodibility.

- Use narrow points or boot systems with small wings to grade more repellent soil and root uptake herbicides away from the seed zone or

- Combine seeding systems using small wings with banded surfactant formulations; especially to improve establishment in more repellent parts of the paddock and parts that shed harvested water easily (e.g. slopes and ridges).

Built-in benefits of the furrow systems in the above methods are the improved water harvesting to make small rainfalls more effective, reduced evaporative loss by the dry patch in the ridges, deeper furrows which sow more easily onto moisture and retention of some nutrition and fertiliser for slow release later in a wetter season when the soil wets up. Technical challenges of the furrow sowing are sowing the seed too deep and risk of furrow fill, increased leaching in wetter seasons and delayed weed emergence from dry ridge centres.

2) The amelioration options aim to remove the water repellence over the medium to long-term (Table 1). They are more expensive and often slow to implement and involve both physical displacement and some mixing of the repellent topsoil or the overcoming of the repellence by claying. These options have additional agronomic risks and opportunities.

Table 1. Summary of the main management options for water repellent sandplain soils

|

Type |

Management Option |

Typical cost ($/ha) |

Longevity (years) |

Mechanisms |

|

Mitigation |

Improved furrow sowing (modified seeding systems and on-row seeding) |

<5 |

1 |

Grading of repellent soil into ridges, water harvesting, preferential flow of water via remnant crop root systems |

|

Banded wetting agent |

$8-15/year |

1 |

Surfactant component aids water penetration into furrow base; improved formulations also help retain water and nutrients. |

|

|

Blanket wetting agent +/- water adsorber |

$25-100/year |

1-2 |

Aids water penetration into and retention in topsoil |

|

|

Amelioration |

One-way ploughing |

40-60 |

3 |

Dilution and turnover of OM |

|

Rotary spading |

$120-150 |

3+ |

Soil heterogeneity provides pathways for water entry |

|

|

Soil inversion (mouldboard or square plough) |

$100-150/ha |

5+ |

Inversion of wettable subsoil layer to the surface |

|

|

Clay spreading or Clay delving |

$400-900/ha |

>10 |

Higher soil surface area & clay content masks repellence and improves microbial habitat for better wax consumption |

This paper will focus on the effectiveness and role of mitigation strategies including improved Min-till furrow sowing techniques and banded wetting agents and also on the amelioration of soil water repellence through the use of one-off deep cultivation in WA.

Improved Min-Till furrow sowing

The principle aim of furrow sowing is to improve crop establishment by grading repellent soil out of the planting area, seeding below the repellent layer into wettable subsurface soil and enabling harvesting following rain into the furrow. In WA there is clear evidence that furrow sowing with narrow knife points is often not effective in improving crop establishment in repellent soils. It is commonly observed that where establishment is poor in furrows created with knife points the furrow itself will be dry and often the ridges will be wetter than the furrows! In terms of crop establishment there will be gaps in the crop rows and delayed, staggered emergence with the severity depending on the degree of water repellence. The evidence suggests that dry, water repellent soil flows around the knife point into the furrow and is concentrated with the seed and fertiliser. We have been investigating a number of approaches to try and improve the effectiveness of furrow sowing:

1. Use of winged points or boots to create lift in the furrow walls during seeding and reduce the flow of repellent soil into the furrow, improve grading of repellent topsoil out of the furrow, and in some cases, such wings when set deeper can also help lift (delve) moist soil into the seed zone from subsurface layers.

2. Paired row or ribbon seeding by possible combinations of winged seeding boots, splitter boots, wider closer plates and wider press wheels increase the crop rows/area sown with increased likelihood of intercepting wet soil and possible seed placement benefits (e.g. “Stiletto” systems which cost about $250/tine for full point replacement).

3. Use of banded wetting agent formulations applied into the furrow behind the press wheel to achieve more consistent wetting of the repellent soil.

4. Sowing in or near the previous years crop rows to benefit from the preferred pathway, old roots and macropores for water entry long residual crop root systems and stubbles, as well as residual moisture which may have accumulated there from previous rain.

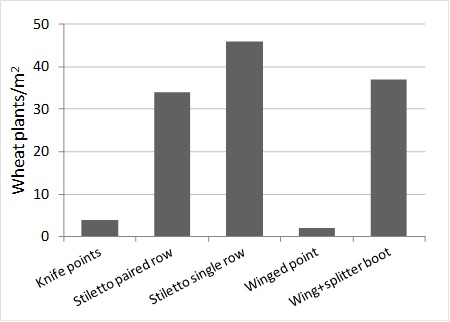

With early dry or partially dry sowing a winged paired row seeding boot (Stiletto paired) or winged boot with a single row (Stiletto single) or winged point with splitter boot gave much better early wheat emergence on a severely repellent pale deep sand than standard narrow knife points (Fig. 1).

Figure 1. Early wheat emergence with different seeding systems at Mingenew in 2013, sown on 24 April 2013 with shallow subsurface moisture at approximately 4 cm. all low pressure presswheels (2kg/cm width). The Stiletto boots are attached to the back of the knife points, reason for poor moisture delving of the winged point unclear.

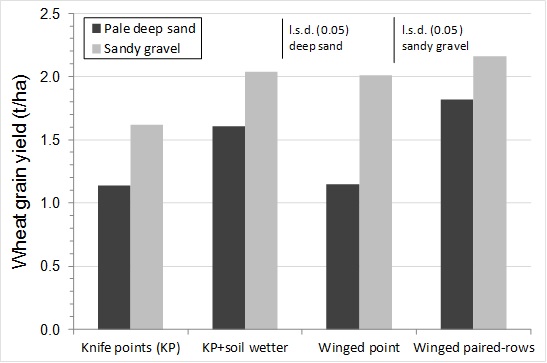

In a trial on severely repellent (MED~3) pale deep sand and sandy gravel in 2012 use of banded soil wetting agent or a winged seeding boot with paired rows corresponded to significantly improved wheat emergence (data not shown) and higher grain yield, on both soil types (Fig. 2). Winged points gave a benefit from shallow moisture delving on the sandy gravel but no benefit on the pale deep sand which had a greater depth of dry sand. With better establishment the crop competed better with the grass weeds, predominantly Brome grass.

Figure 2. Impact of seeding systems on wheat grain yield at Badgingarra in 2012, sown on 17 May with dry soil over some soil moisture which was shallower on the sandy gravel. KP+soil wetter = knife points plus banded wetting agent. (325 mm Apr-Oct rainfall).

In the 2012 trial (Fig. 2) banded wetter gave yield increases of over 600 kg/ha on both soil types. Winged points gave a benefit of nearly 500 kg/ha on the sandy gravel but no benefit on the pale deep sand. The paired row seeding boots gave the highest yield response over knife points with nearly a 1t yield increase on the pale deep sand and a 650 kg/ha yield increase on the sandy gravel. The grower’s crop surrounding the trial was sown much later with a standard knife point seeder when the soil had wetted up more and performed much better than the early sown knife point plots into drier soil.

In this trial there was no benefit of banded wetter on early emergence, which came from soil moisture at seeding, but with a subsequent 20 mm rain event 3 weeks after sowing there was increased emergence in the banded wetting agent treatment (data not shown).

Paired-row seeding incorporating winged seeding boots has also shown benefits in large-scale on farm trials. In 2011 a paired row seeder gave paddock average yield increases of 200-500 kg/ha compared to knife point seeders with good seeding conditions and variable soil types and levels of water repellence in the paddock. On a severely repellent (MED=4.7) sandy gravel average volumetric soil moisture content (0-5 cm) shortly after seeding was 2.2% in the furrow and 4.8% in the ridge for the knife point seeder and 4.2% in the furrow and 2.6% in the ridge for the paired row seeder.

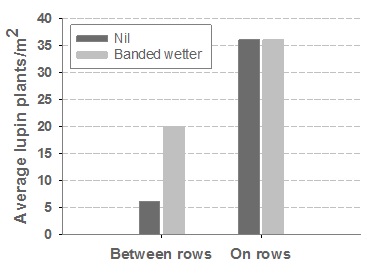

Crop placement in relation to the previous year’s crop rows can also improve crop establishment as the remnant stubble and root systems of the previous year’s crop provide preferred pathways for water entry by preceding rain. For example, banded wetting agent improved crop establishment for dry sown lupins sown between the previous year’s wheat rows but sowing on the previous year’s wheat rows gave a much greater crop establishment benefit and the benefit of the banded wetter was negated (Fig. 3)

Figure 3. Dry sown lupin establishment on a moderately repellent deep pale yellow sand when sown dry in May either between or on the previous year’s wheat rows and with or without (Nil) banded wetting agent at Balla after summer rain in 2011.

Banded wetting agents

The aim of banded wetting agents is to make the initial wetting up of the furrow much more consistent. Wetting agents are applied, ideally in a continuous stream to the base of the furrow behind the press wheels. Numerous products are available but in essence most act as surfactants reducing the surface tension of the water allowing the soil to wet up more easily and drain more easily which can result in reduced water retention and increased leaching. Many products are biodegradable and short lived or include water and nutrient adsorbing compounds to reduce the leaching impacts from the wetting agent. Banding the wetting agents allow relatively small amounts of product to be used, typically 1-2 L/ha, making them more cost effective than blanket applications which can be very expensive given their relatively short-lived benefits.

In 2012 a common and proven wetting agent (short duration penetrant) was used in 12 trials in the northern and southern agricultural regions (Table 2). Five of the trials had a significant grain yield responses of 200-800 kg/ha (Table 2). Half of the sites either had no yield response or one trial had a negative yield response although yields were low and variable at the site (Table 2).

The results highlight one of the principal concerns with the use of banded wetting agents; variable response and lack of reliability. Some of the factors involved in the variable response are technical setup issues while others appear to do with product efficacy and timing in relation to sowing date, soil moisture conditions, rainfall events and possibly soil types.

Essentially the banded stream of wetting agent should hit stationary soil at the base of the furrow, so it is not buried, remains at the surface and can come into contact with the water harvested from the ridge wall into the furrow. Using rounded or ‘V’-shaped press-wheels can minimise the risk of furrow collapse and infill and also prevent the furrow side walls being ripped up, which can occur with more rectangular shaped press-wheels creating a tumbling mass of soil behind the press wheel and poor product placement.

Table 2. Summary of grain yield responses to application of banded wetting agent on moderate to severely repellent soils in WA in 2012 (GSR = growing season Apr-Oct rainfall; ns = not significant).

|

Location |

Soil type |

Crop type |

Seeding date |

GSR (mm) |

Grain Yield (t/ha) |

Yield diff. |

|

|

Control |

Banded Wetter |

||||||

|

Binnu |

Sandy earth |

Lupin |

1 May |

133 |

1.5 |

1.7 |

+0.2 |

|

Badgingarra |

Sandy gravel |

Canola |

12 May |

325 |

1.4 |

1.4 |

ns |

|

Badgingarra |

Sand |

Lupin |

14 May |

325 |

2.1 |

2.4 |

ns |

|

Badgingarra |

Sandy gravel |

Lupin |

14 May |

325 |

2.1 |

2.2 |

ns |

|

Badgingarra |

Sand |

Wheat |

17 May |

325 |

1.1 |

1.6 |

+0.5 |

|

Badgingarra |

Sandy gravel |

Wheat |

17 May |

325 |

1.6 |

2.0 |

+0.4 |

|

Nyabing |

Loamy sand |

Barley |

23 May |

222 |

2.8 |

2.7 |

ns |

|

Cordering |

Loamy gravel |

Barley |

24 May |

322 |

4.7 |

4.5 |

ns |

|

Frankland |

Loamy gravel |

Wheat |

28 May |

295 |

2.7 |

3.5 |

+0.8 |

|

Cranbrook |

Loamy gravel |

Barley |

30 May |

291 |

2.4 |

2.8 |

+0.4 |

|

Frankland |

Sand |

Wheat |

4 June |

295 |

1.0 |

0.7 |

-0.3 |

|

Warradarge |

Sand |

Barley |

28 June |

399 |

1.7 |

1.5 |

ns |

Provided the technical setup is correct larger responses to banded wetting agent are seen with early sowing into dry or partially dry conditions.

One-off deep cultivation

One-off deep soil cultivation is being viewed as strategic soil renovation intervention which aims to address a number of soil and agronomic constraints with the one operation. Following this one-off intervention minimum tillage continues to be used on these soils. A move back to more regular shallow soil cultivation is not advocated at all and would be highly detrimental.

The principal sandplain soil constraints in WA include subsoil acidity, subsoil compaction, soil water repellence and poor water and nutrient holding capacity. In addition herbicide resistant weeds are typically ranked by growers as the biggest threat to the sustainability of cropping on these soils. In all cases one-off deep cultivation is being considered and in some cases used by growers to overcome several of these constraints at the one time.

The mechanism by which one-off deep cultivation overcomes soil water repellence depends on the cultivation method used. Rotary spaders partially bury and mix (dilute) the repellent topsoil into the subsoil to a depth of 25-35 cm. Critically the spades also lift seams of wettable subsoil to the surface and water and dye infiltration observations indicate that these seams of wettable subsoil act as preferred pathways for water entry. The increased number of these pathways aids the wetting up of the soil profile. Maintenance of these preferred pathways is important for improved wetting up so subsequent mixing should be minimised with ongoing use of minimum tillage.

Rotary spading in the absence of additional clay-rich subsoil will not completely remove the soil water repellence and this will impact on the longevity of the benefits. In WA, lime incorporation is another critical driver for rotary spading as the spader does a better job of mixing the lime throughout the profile than a complete soil inversion.

Complete soil inversion using either a mouldboard or square plough completely inverts the soil so that a layer of subsoil covers the topsoil which is typically buried at 20-35 cm depth. Dye infiltration shows that when inversion is done well, the surface layer wets up completely and contact with wet soil and hydraulic pressure helps the buried repellent topsoil wet up. Almost complete burial of herbicide resistant weed seeds is possible with effective inversion and this is sometimes a more important factor for soil inversion than managing water repellence per se. The soil needs to be wet for effective inversion and mouldboard ploughs need to be fitted with skimmer blades which sit ahead for the main mouldboard shares and scrape the topsoil into the base of the furrow before the subsoil is folded on top.

Soil analyses have shown that soil inversion can effectively remove repellence and removes compaction to the working depth (Table 3). The soils are however, very susceptible to re-compaction, so controlled traffic is recommended to optimise the compaction removal benefits and minimise re-compaction. On sandplain soils with a gradational increase in clay content (Table 3 – Binnu site) with depth, deep cultivation can increase the topsoil clay content to levels similar to those achieved with claying. It should be noted that the gentler folding action of the mouldboard plough has less impact on organic carbon stocks in soils than the more aggressive mixing of the rotary spader which results in some organic carbon losses.

Table 3. Impact of mouldboard ploughing and rotary spading (Spader) on the mass of organic carbon, topsoil clay %, water droplet penetration time (WDPT; 0-10 cm) and penetration resistance using a cone penetrometer compared with an untreated control on two sandplain soil types in Western Australia.

|

Soil type (Site location) |

Treatment |

Mass Organic Carbon (t/ha) |

Clay% |

WDPT (s) |

Penetration Resistance (MPa) |

||||

|

0-10 cm |

10-20 cm |

20-30 cm |

Tot. 0-30 |

0-10 cm |

0-10 cm |

@20cm |

@30 cm |

||

|

Deep yellow sandy earth (Binnu) |

Control |

7.6 |

4.0 |

1.6 |

13.1 |

3.5 |

7 |

1.8 |

2.7 |

|

Spader |

4.0 |

3.3 |

3.4 |

10.7 |

4.2 |

3 |

0.6 |

1.5 |

|

|

Mouldboard |

3.6 |

6.1 |

3.5 |

13.2 |

5.5 |

0 |

0.4 |

1.1 |

|

|

Pale deep sand (Badgingarra) |

Control |

12.8 |

5.6 |

3.1 |

21.5 |

3.7 |

320 |

2.8 |

4.0 |

|

Spader |

7.3 |

8.6 |

3.7 |

19.6 |

2.9 |

11 |

1.3 |

3.1 |

|

|

Mouldboard |

5.1 |

10.8 |

9.7 |

25.6 |

2.7 |

1 |

0.6 |

0.9 |

|

Crop yield responses to soil inversion with a mouldboard plough (Table 4) or rotary spading (Table 5) can be large and average yield responses in the first year are typically of the order of 500-600 kg/ha. Yield responses tend to be greater for cereal crops although some good lupin and canola yield increases have been measured. Larger yield responses tend to occur in more strongly repellent soils with good yield potential (e.g. Table 4, Sites 1 and 3; Table 5, Sites 7 and 9) and these have greater benefits in subsequent years. Weed control is a significant advantage at some sites (Table 4, Sites 6 and 10). Lower yield responses are sometimes associated with lower repellence (e.g. Table 4, Site 6), presence of other constraints (e.g. subsoil acidity Table 4, Site 9; Table 5, Site 5), poor inversion (e.g. Table 4, Site 4) and implementation problems such as seeding depth, wind erosion (sand blasting, furrow infill) and surface crusting.

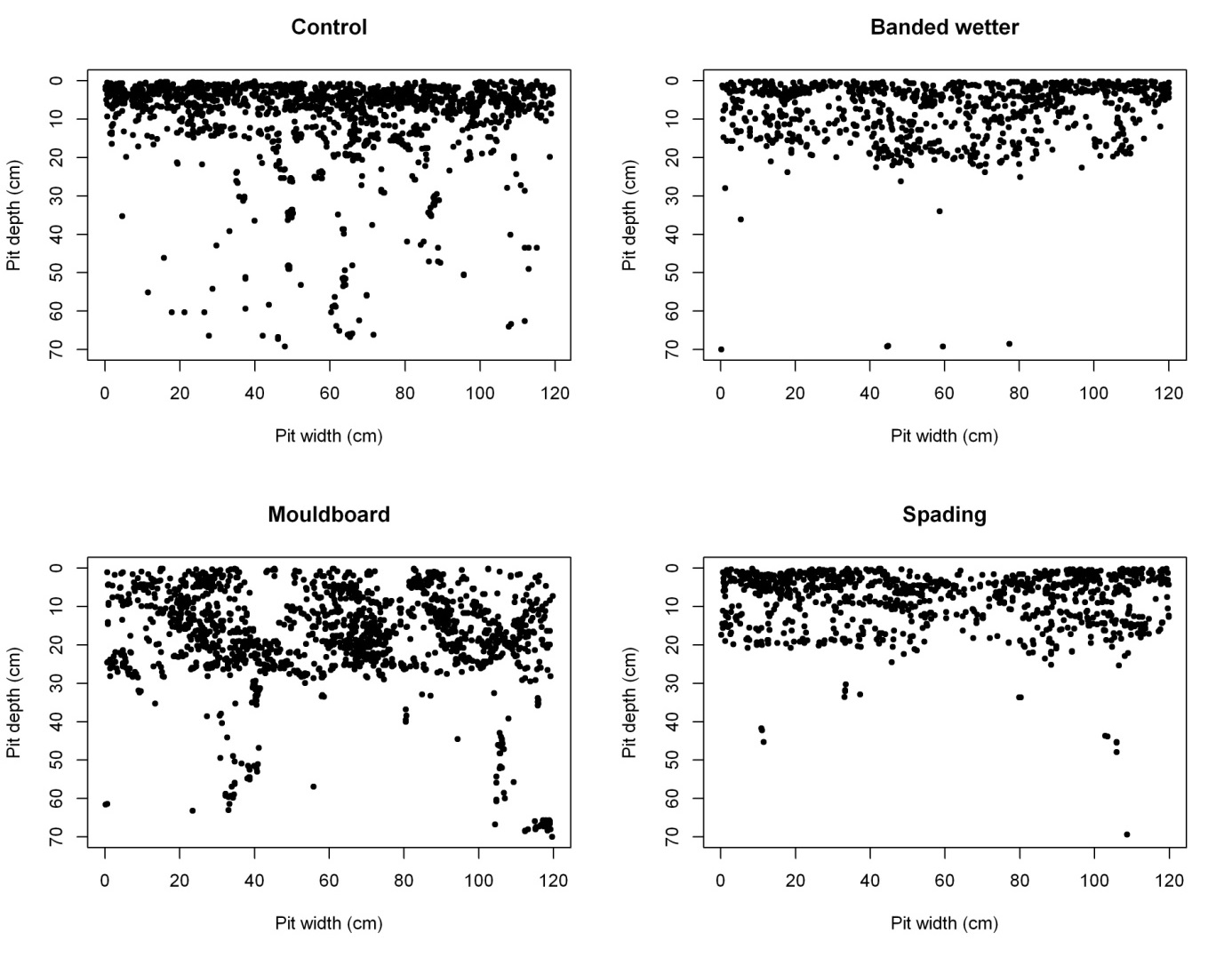

In addition to amelioration of water repellence, yield benefits from deep soil cultivation can be attributed to numerous factors including a cultivation effect, a deep ripping/compaction removal effect, weed and disease control, N mineralisation and improved nutrient access which is associated with changes in root distribution (Fig. 4). In deep yellow sand at Badgingarra, 70% of crop roots were in the top 10 cm for the control whereas, only 26% were for the mouldboard treatment with many more roots in the buried topsoil in the 10-30 cm layer (Fig. 4). This can have advantages as the roots can fully explore the nutrients in the subsoil which stays wetter for longer and is not subject to rapid drying from evaporation. Research has demonstrated that N and P availability and crop uptake is improved after mouldboard ploughing or rotary spading (data not shown).

Table 4. Effect of mouldboard ploughing (MBP) on grain yield and change in yield (MBP Diff.) compared with uncultivated control (Con) for a range of water repellent sandplain soils in WA. (*= year ploughed)

|

Site No. |

Location |

Soil Type |

Year |

Crop |

Grain yield (t/ha) |

||

|

Con |

MBP |

MBP Diff. |

|||||

|

1 |

Badgingarra |

Pale sand over gravel |

2010* |

Wheat |

1.0 |

2.2 |

+1.2 |

|

2011 |

Lupin |

1.3 |

1.8 |

+0.5 |

|||

|

2 |

Badgingarra |

Brown deep sand |

2010* |

Wheat |

0.5 |

1.0 |

+0.5 |

|

3 |

Badgingarra |

Pale deep sand |

2010* |

Barley |

0.8 |

2.0 |

+1.2 |

|

2011 |

Lupin |

0.8 |

1.8 |

+1.0 |

|||

|

2012 |

Barley |

1.4 |

2.7 |

+1.3 |

|||

|

4 |

Balla |

Deep yellow sandy earth |

2011 |

Wheat |

2.7 |

2.8 |

+0.1 |

|

2012 |

Lupin |

1.5 |

1.4 |

-0.1 |

|||

|

5 |

Binnu |

Deep yellow sandy earth |

2009* |

Wheat |

1.4 |

1.9 |

+0.5 |

|

2011 |

Wheat |

2.7 |

3.2 |

+0.5 |

|||

|

2012 |

Wheat |

0.6 |

1.1 |

+0.5 |

|||

|

6 |

Casuarina |

Deep yellow sandy earth |

2007* |

Barley |

0.7 |

0.8 |

+0.2 |

|

2008 |

Canola |

1.5 |

1.4 |

-0.1 |

|||

|

2009 |

Wheat |

3.6 |

4.0 |

+0.4 |

|||

|

2010 |

Lupin |

1.6 |

1.6 |

0 |

|||

|

2011 |

Wheat |

5.1 |

5.5 |

+0.4 |

|||

|

2012 |

Lupin |

1.6 |

1.5 |

-0.1 |

|||

|

7 |

Gibson |

Pale deep sand over clay |

2012* |

Wheat |

1.0 |

1.7 |

+0.7 |

|

8 |

Nabawa |

Deep yellow sandy earth |

2010* |

Wheat |

1.4 |

1.9 |

+0.5 |

|

9 |

Nabawa |

Deep yellow sand |

2011* |

Wheat |

2.9 |

2.9 |

0 |

|

2012 |

Lupin |

0.8 |

0.8 |

0 |

|||

|

10 |

Neridup |

Pale deep sand over gravel |

2011* |

Barley |

2.6 |

3.3 |

+0.7 |

|

2012 |

Canola |

2.3 |

3.4 |

+1.1 |

|||

|

11 |

Marchagee |

Yellow deep sand |

2012* |

Wheat |

0.8 |

1.5 |

+0.7 |

Table 5. Effect of rotary spading (SP) on grain yield and change in yield (SP Diff.) compared with uncultivated control (Con) for a range of water repellent sandplain soils in WA. (*= year treated)

|

Site No. |

Location |

Soil Type |

Year |

Crop |

Grain yield (t/ha) |

||

|

Con |

SP |

SP Diff. |

|||||

|

1 |

Badgingarra |

Pale deep sand |

2009* |

Canola |

n/a |

n/a |

- |

|

2010 |

Wheat |

0.5 |

1.0 |

+0.5 |

|||

|

2011 |

Lupin |

0.3 |

0.4 |

+0.1 |

|||

|

2 |

Balla |

Deep yellow sandy earth |

2011* |

Wheat |

2.7 |

3.4 |

+0.7 |

|

2012 |

Lupin |

1.5 |

1.7 |

+0.2 |

|||

|

3 |

Binnu |

Yellow deep sand |

2010* |

Wheat |

1.2 |

1.9 |

+0.7 |

|

4 |

Binnu |

Deep yellow sandy earth |

2009* |

Wheat |

1.4 |

1.9 |

+0.5 |

|

2011 |

Wheat |

2.2 |

2.2 |

0 |

|||

|

2012 |

Wheat |

0.6 |

0.9 |

+0.3 |

|||

|

5 |

Nabawa |

Deep yellow sandy earth |

2011* |

Wheat |

2.9 |

2.4 |

-0.5 |

|

2012 |

Lupin |

0.8 |

0.7 |

-0.1 |

|||

|

6 |

Marchagee |

Deep yellow sandy earth |

2010* |

Wheat |

2.4 |

3.5 |

+1.1 |

|

7 |

Marchagee |

Pale yellow deep sand |

2011* |

Wheat |

1.5 |

3.3 |

+0.8 |

|

8 |

Marchagee |

Yellow deep sand |

2012* |

Wheat |

0.8 |

1.3 |

+0.5 |

|

9 |

Moora |

Pale sand over gravel |

2010* |

Wheat |

1.4 |

3.4 |

+2.0 |

|

10 |

Warradarge |

Pale deep sand |

2010* |

Wheat |

0.7 |

1.1 |

+0.4 |

Figure 4. Wheat root interception diagrams on a soil pit face in deep yellow sand at Badgingarra in untreated (control), rotary spaded or mouldboard ploughed soil. Each dot represents a wheat root at the soil pit face.

Wind erosion following complete stubble burial is one of the biggest risks associated with these practices. While this risk cannot be completely avoided it can be minimised by only deep cultivating wet soil followed by immediate seeding of a cereal cover crop. Packing the soil smooth with a roller can increase the risk of wind erosion and it is better to leave the soil ridged. Seeding too deep is also a particular challenge and growers typically use light bars with shallow working points or flexible trailing seeding boots to minimise the risk of seeding too deep. Some growers have successfully broadcast seed onto wet soil and rolled it in with packers to establish cover. Several growers on the south-coast of WA have developed systems to seed immediately behind their mouldboard/square ploughs in a one pass operation.

Conclusion – Strategies for water repellent sand

The research demonstrates that in many cases crop establishment is being compromised through the use of narrow knife points, especially with early sowing into dry or partially dry soils. Looking at what options there might be to improve the reliability and effectiveness of minimum tillage furrow sowing systems on water repellent soils is a good starting point. This may involve testing different seeding points and/or boots, changes in seed placement to sow on or near the previous year’s row or use of a banded soil wetting agent. Many of these modifications can initially be trialled on parts of the seeder to see if they are valuable or have other complications or impacts in other soil types. Generally these approaches are relatively low cost and have few risks and once implemented the benefits may be obtained across the majority of water repellent soils on the farm. These approaches also maintain the benefits of water harvesting and concentration of rainfall into the crop roots zone which may be increasingly important as the frequency of warmer and drier seasons increase.

Amelioration methods including deep cultivation or claying approaches can give significant yield increases but they are expensive, slow to implement, can sometimes be technically challenging and often have associated risks which may negate some of the benefits. For this reason these options should be implemented carefully and strategically. It may be that these can be targeted at those repellent soils that have good yield potential if the repellent problem was overcome but have not shown marked improvement from improved seeding approaches. Like the mitigation approaches the deep cultivation techniques should be tested on a small scale initially to determine if the soils are responsive and to work out how to implement the techniques to maximum advantage.

Once crop establishment is improved, either through improved seeding or soil amelioration, crop root density will be increased and maintaining these remnant roots which act as preferred pathways for water entry with ongoing use of minimum tillage may be an affordable and sustainable system for managing repellent soils (see work of Margaret Roper, CSIRO Perth).

Acknowledgements

This research was funded by GRDC and DAFWA through DAW00204 ‘Delivering agronomic strategies for water repellent soils in WA’. Thanks to Breanne Best, Trevor Bell, Larry Prosser, Steve Cosh and Grey Poulish (DAFWA) for technical support. We acknowledge all the support and effort of the WA growers, grower groups and industry partners who have worked with us.

Contact details

Stephen Davies and Paul Blackwell

WA Department of Agriculture and Food

PO Box 110, Geraldton WA 6530

(08) 9965 8555

stephen.davies@agric.wa.gov.au

GRDC Project Code: DAW00204,

Was this page helpful?

YOUR FEEDBACK