High value products from canola meal

Author: Siong Tan, Adeola Alashi, Samson Agboola, Rodney Mailer and Christopher Blanchard | Date: 27 Feb 2013

Siong H. Tan1, 2, Adeola Alashi1, 2, Samson O. Agboola1, 2, Rodney J. Mailer3, Christopher L. Blanchard1, 4

1E.H. Graham Centre for Agricultural Innovation, Wagga Wagga, NSW 2650; 2School of Agricultural and Wine Sciences, Charles Sturt University, Wagga Wagga, NSW 2678; 3NSW DPI, Pine Gully Road, Wagga Wagga, NSW 2650; 4School of Biomedical Sciences, Charles Sturt University, Wagga Wagga, NSW 2678.

GRDC project code: UCS00015

Keywords: canola, proteins, value, meal, ingredient, functionality

Take home message

- Currently under-utilised canola meal has been identified as a potential source for the development of high value food grade proteins.

- Recovery of up to 70% proteins from oil-free meal was demonstrated.

- The current industrial toasting process decreased protein extraction yield by 40%.

- Some canola proteins have good technological functionality compared to proteins currently being used for food manufacturing.

- Our group has also demonstrated pharmaceutical activities of proteins from canola meal.

- Food ingredients and pharmaceutical products are potentially high value products which will add value to the canola industry.

Production of canola in Australia was at a record 3.2 million ton in 2011/12 (AOF Crop Report, December 2012). The average oil content for the harvest was 44.0% in whole seed, and the average protein content was 37.9% in oil-free meal (Seberry et al., 2011). The potential use of Australian canola meal has not been fully explored. The protein-rich canola meal left after the oil extraction is generally used as a protein source in livestock and aquaculture industries (Canola Council of Canada, 2009). The continuous growth in canola production worldwide will result in further increases in the abundance of canola meal which provides the opportunity to develop high market value products, such as functional protein extracts for human food applications.

Canola meal has been identified as a potential alternative protein source for human consumption due to its nutritional value and technological functionality (Aider & Barbana, 2011; Tan et al., 2011a). Canola proteins are known to have well balanced amino acid composition (Pastuszewska et al., 2000) comparable to the international requirement for adults and young children (FAO/WHO/UNU, 1985). This has encouraged the further study into canola proteins for human food applications in order to enhance the value of the currently under-utilised canola meal. Our research examines the feasibility of using Australian canola meal as a raw material for human food grade protein based ingredients. We have investigated the protein extraction methodology and verified the human consumption safety of these extracts. Other than the food technological functionality, our group has also demonstrated very high value pharmaceutical applications of canola proteins.

Canola proteins were extracted successfully from canola meal using the Osborne method as documented in Tan et al. (2011a). This method involves the sequential extraction of four different types of canola proteins (albumin, globulin, glutelin, and prolamin fractions; Table 1). Albumin and globulin extracts show high potential as food ingredients, hence, will be the focus of this paper.

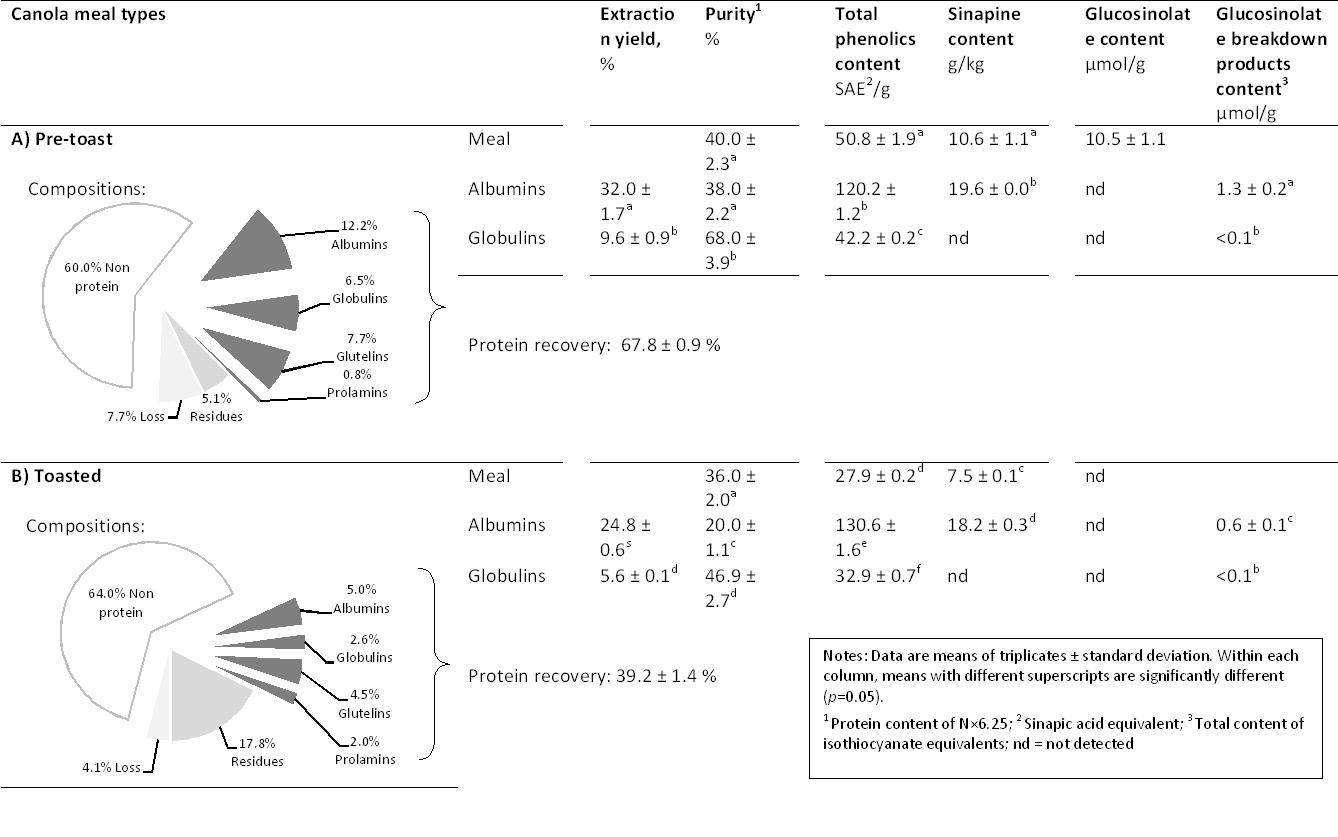

Table 1 shows the comparison of protein extraction yield for toasted and pre-toast canola meal. Albumin extracts were the major fraction. Albumin yield from canola pre-toast meal (32.0%) was significantly higher than that of canola toasted meal (24.8%). Globulin yield from both meal samples was significantly lower (9.6%, pre-toast; 5.6%, toasted). Although both of the globulin extracts were of higher purity, the calculated amount of pure globulins as shown by the pie charts was still lower than that of albumins. A total of 67.8% of proteins contained in pre-toast meal was recovered, compared to only 39.2% for toasted canola meal. This suggests that pre-toast canola meal is more suitable for protein extraction. The toasting process, although it is essential for the recovering of oil extraction solvent, had apparently affected the protein extraction yield and also purity.

Previous studies have shown that the presence of antinutritional factors such as glucosinolates and major phenolic compounds including sinapine and tannins, has restricted the incorporation of canola meal in human food (Wu & Muir, 2008; Yoshie-Stark et al., 2008). Our recent study has concluded that glucosinolate content of all the protein fractions was below the detection limit (<3 µmol/g, Tan et al., 2011b). Sinapine was not detected in globulin extracts, whereas albumin extracts contained sinapine level of 18.2-19.6 g/kg depending on the type of meals for protein extraction. A further study carried out recently also confirmed that, level of glucosinolate breakdown products was negligible in the protein extracts (<1.3 ± 0.2 µmol/g, unpublished results). This finding suggests that canola protein extracts may be considered as safe ingredients. However, if this fraction of canola meal protein is to be used as a human food ingredient, further study is still needed to investigate the effect of sinapine at such levels to human health.

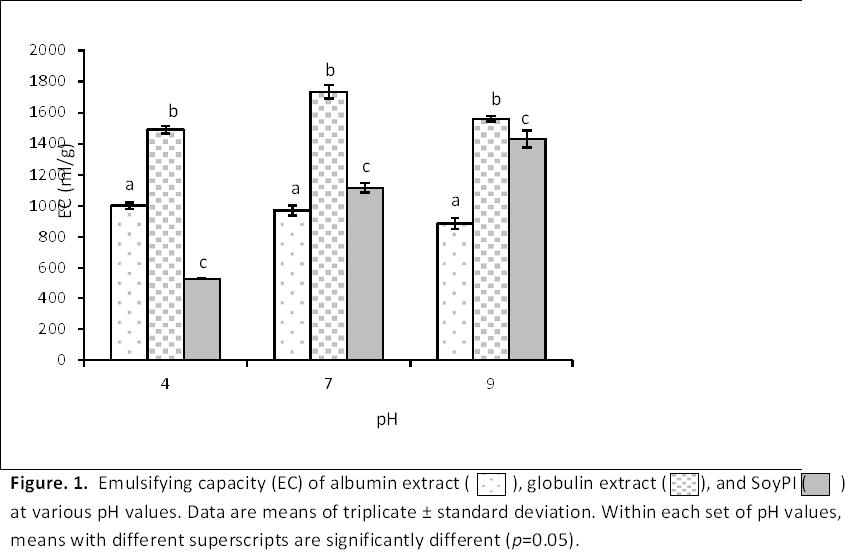

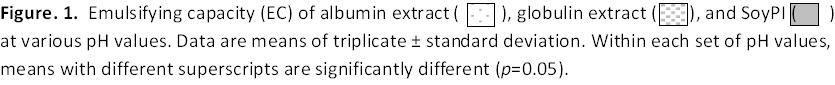

Technological functional properties of proteins are crucial as protein is often added to food to provide emulsifying and gelling properties. Emulsifying capacity (EC) is a measure of a protein’s ability to form emulsions. An emulsion is a homogenous mixture of two immiscible liquids such as oil and water. Proteins with a higher EC are more likely to form smaller and more stable emulsion droplets. Our study shows that globulin extracts had significantly higher emulsifying capacity (EC) than albumin extracts and SoyPI at all pH values tested (Figure 1). Figure 2 shows that globulin extract-stabilized emulsions had smaller droplet sizes than that of albumin extract-stabilised emulsions at all pH values. The same trend was observed for SoyPI except for pH 9 at which SoyPI-stabilised emulsion had smaller droplet compared to that of globulin extracts even though the EC was not as good. Figure 2 also shows that the stability of canola protein based emulsions were comparable to those of SoyPI based emulsions at all pH values with no significant (p>0.05) changes in droplet size during storage for up to 7 days at room temperature.

Albumin and globulin extracts showed better gelling property than SoyPI as measured by complex modulus (G*). G* is an indication of resistance of gel structure to deformation. At both pH 7 and 9, canola albumin and globulin extracts were good heat-set proteins, whereas SoyPI was not able to form a gel with appreciable G*. Higher G* is related to a stronger gel structure. SoyPI formed gel only with the addition of salt (0.2M NaCl). However, the gel strength was still not as strong as the globulin gel without salt. This suggests the possible use of globulin extracts as an ingredient in healthy low salt food products. These findings demonstrate that emulsifying and gelling properties of canola albumin and globulin extracts are very comparable if not better than the commercially available SoyPI in some situations, suggesting the potential use of the canola proteins in food applications.

Canola protein hydrolysates are another potential high value product generated by enzymatic treatment of proteins to produce peptides. Some hydrolysed proteins have bioactive properties which have been reported as having in vitro or in vivo physiological functionality that could prevent or attenuate disease, or augment conventional therapies. Preliminary work in our group has demonstrated antioxidant property of canola hydrolysates (Alasahi, personal communication). The antioxidant activity of canola hydrolysates was 25.8-35.6%. Different enzymes produced protein hydrolysates of different antioxidant activity. Canola protein hydrolysates with anti oxidant properties can help in the removal of excessive free radicals which could lead to body cell damage. Canola protein hydrolysates also show possible antihypertensive properties (control of high blood pressure). ACE and rennin are enzymes responsible for high blood pressure. Canola protein isolates, after enzymatic treatment, were found to inhibit rennin activity up to 63%, and ACE activity up to 80%. Both antioxidant and antihypertensive activities of canola proteins hydrolysates are similar to, if not better than those obtained from other protein sources like soy, peas, and flaxseed.

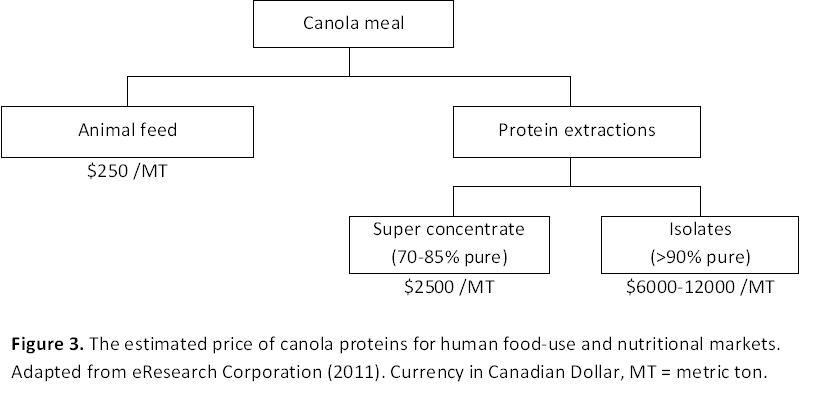

The commercial extraction of proteins from canola meal has gained momentum since canola proteins have been classified as “Generally Recognised as Safe” (GRAS) by American Food and Drug Administration (FDA). According to a Canadian market report by eResearch Corporation (2011), a Canadian company (BioExx Specialty Proteins Ltd.) targeting human food-use and nutritional markets, sell protein isolates for at least 10 times the price of regular meal (Fig. 3). Further purification of the protein isolates have been estimated as having a value of up to CAD$12000 per metric ton (eResearch Corporation, 2011). It has been reported that the production of canola protein products essentially tripled the revenue per metric ton of canola meal. Canola protein products are a potentially high value product which will add value to the canola industry. As shown in our study, proteins prepared using the Osborne method are potentially functional and safe food ingredients. Further value adding can be achieved by generating protein hydrolysates, which appear to have pharmaceutical applications. Canola proteins could be an important part in the expanding global proteins market, which is a multi billion market with enormous growth every year (eResearch Corporation, 2011).

Table 1. Protein yield and anti-nutritional content of meal samples and selected protein extracts.

References

Aider, M., & Barbana, C. (2011). Canola proteins: composition, extraction, functional properties, bioactivity, applications as a food ingredient and allergenicity - A practical and critical review. Trends in Food Science & Technology, 22(1), 21-39.

AOF Crop Report (December 2012). Australia Square, Sydney, NSW: Australian Oilseeds Federation.

Canola Council of Canada (2009). Canola Industry. Overview of Canada's canola industry. Retrieved 16 October, 2009, from http://www.canolacouncil.org/ind_overview.aspx

eResearch Corporation (2011). Stock Potentials: BioExx Specialty Protiens Ltd. Toronto, Ontario: eResearch Corporation.

FAO/WHO/UNU (1985). Energy and protein requirements. Report of a Joint FAO/WHO/UNU Expert Consultation. Geneva.

Pastuszewska, B., Ochtabinska, A., & Morawski, A. (2000). A note on the nutritional adequacy of stock diets for laboratory rats and mice. Journal of Animal and Feed Sciences, 9(3), 533-542.

Seberry, D. E., Parker, P. A., & Ayton, J. G. (2011). The Quality of Australian Canola 2011-12: Australian Oilseeds Federation, NSW Department of Primary Industries, Australia.

Tan, S. H., Mailer, R. J., Blanchard, C. L., & Agboola, S. O. (2011a). Canola proteins for human consumption: extraction, profile, and functional properties. Journal of Food Science, 76(1), R16-R28.

Tan, S. H., Mailer, R. J., Blanchard, C. L., & Agboola, S. O. (2011b). Extraction and characterization of protein fractions from Australian canola meals. Food Research International, 44(4), 1075-1082.

Wu, J., & Muir, A. D. (2008). Comparative structural, emulsifying, and biological properties of 2 major canola proteins, cruciferin and napin. Journal of Food Science, 73(3), C210-C216.

Yoshie-Stark, Y., Wada, Y., & Wasche, A. (2008). Chemical composition, functional properties, and bioactivities of rapeseed protein isolates. Food Chemistry, 107(1), 32-39.

Contact details,

Siong Tan,

Charles Sturt University, School of Ag and Wine Sciences, NSW 2678

02 6933 2085

GRDC Project Code: UCS00015,

Was this page helpful?

YOUR FEEDBACK