STARTER P REQUIREMENTS - DOES ROW SPACING MATTER AND DO FLUIDS HAVE A BENEFIT?

| Date: 21 Sep 2010

Background

Adequate phosphorus (P) is not only an essential component of profitable and sustainable crop production but is also an increasing component of crop gross margins. In recent years there have been considerable price movements for phosphatic fertilisers leading to interest in ways to improve P fertiliser use efficiency.

There has been a considerable increase in the use of liquid fertilisers especially for the supply of nitrogen for crop production. There are also several products available from a range of suppliers for use as a starter fertiliser to provide P and micronutrients. Research in SA on highly calcareous soils (20-90%) has shown that there can be benefits in using liquid fertilisers over the traditional granular forms (Holloway et al 2001). Soils in northern NSW have CaCO3 concentrations much less than those found in the calcareous soils of SA.

McBeath et al. (2007) reported on dry matter responses to liquid and granular P fertilisers from soils collected from around Australia. 6 soils from the northern grains region were studied with CaCO3 ranging from undetectable to 1.3%. 5/6 of these soils had positive dry matter responses to liquids greater then when granular products were used. One of the key conclusions was that grain yield responses to liquid P needed to be assessed under field conditions.

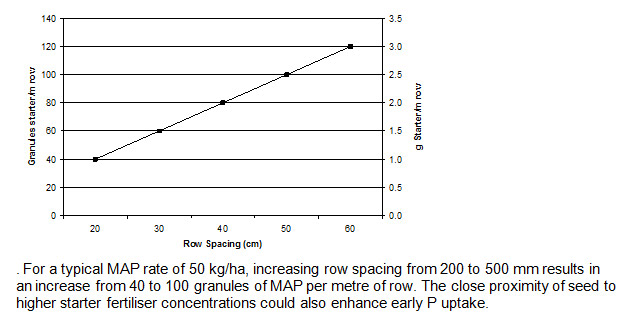

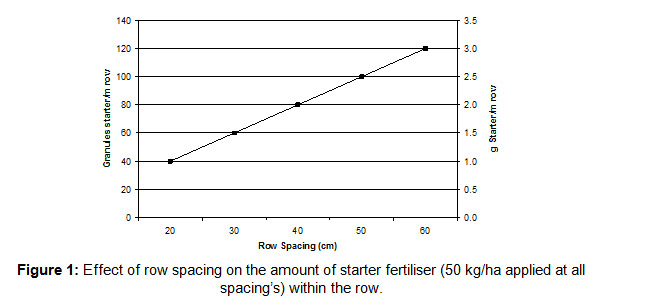

In addition to the increasing availability of liquid fertilisers there has been wide-scale adoption of no-tillage systems and increasing use of inter-row sowing in the northern grains region. In these cropping systems we have also seen a consistent move to wider row spacing’s to improve the stubble handling capacity of sowing equipment. These changes could alter phosphorus responses in the year of application due to changes in the spatial pattern of P application and increased within-row concentrations of P. The effect of row spacing on within-row fertiliser concentration is shown in

Since the calibration of the main soil P tests that growers and advisors base their fertiliser decisions on were conducted under conventional tillage and narrower row spacing’s we were interested in the effect of increasing row spacing, and therefore increased concentrations of P in the seeding furrow, on P fertiliser responses.

Trials

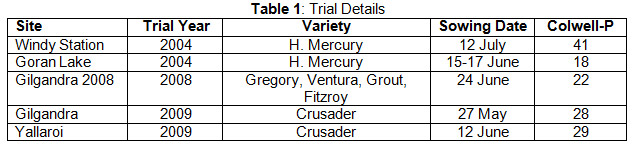

This paper reports on work conducted from a range of trials in 2004, 2008 and 2009. In 2004 collaborative research between NSW DPI and Incitec Pivot investigated crop responses to a range of phosphatic fertilisers, including liquids, at 2 cracking clay sites on the Liverpool Plains.

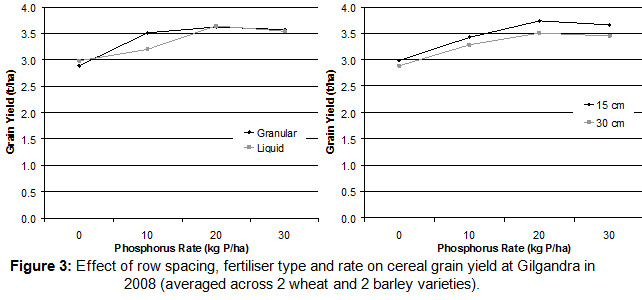

In 2008 one trial was conducted near Gilgandra on a red sandy loam. The trial consisted of a comparison between 2 wheat and 2 barley varieties, grown either at 15 or 30 cm row spacing’s with 4 rates of either granular MAP or liquid P fertiliser – in this case ammoniated phosphoric acid (Easy NP©). As N also varied with the changing P rate, urea was added to balance N application rates.

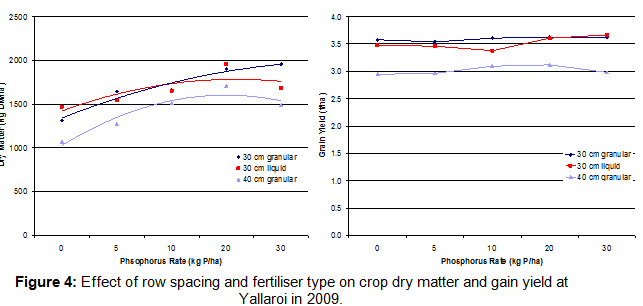

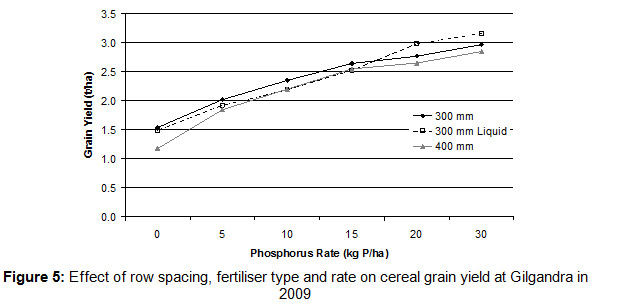

In 2009 trials were established at Gilgandra and Yallaroi. Trials were sown to Crusader wheat, at 30 and 40 cm row spacing with 6 rates of P as granular MAP or ammoniated phosphoric acid (Easy NP©). Dry matter responses were assessed using dry matter harvests and NDVI readings and all grain yield and quality results collected. Again, as N also varied with the changing P rate, urea was added to balance N application rates. Trial details are provided in Table 1.

Results

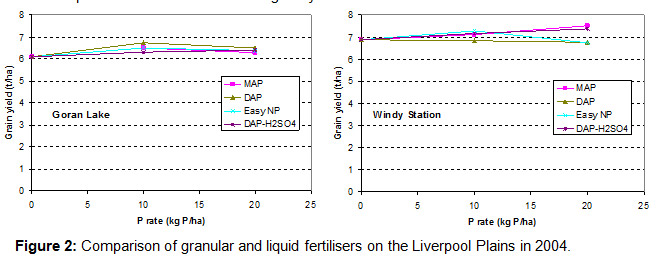

Liquid vs. granular fertilisers

Trials conducted by NSW DPI and Incitec-Pivot Ltd in 2004 under high yield potential on the Liverpool Plains compared wheat responses between liquid starter fertilisers (Easy NP and DAP-H2SO4) and granular products (DAP and MAP). At the “Windy Station” site the Easy NP and the DAP showed no further yield increase from 10 to 20 kg P/ha whereas the other treatments did increase yield further. At the “Goran Lake” trial there was no significant treatment response to added P fertiliser on grain yield.

At Gilgandra in 2008 there was a significant interaction between P rate and the form applied. Liquid P appeared to be less responsive at the lowest applied P rate while there was no difference at the other rates. There was also no evidence of row spacing by P rate interactions although the yield from the narrower row spacing was consistently higher.

In 2009 plant establishment was unaffected by row spacing, P rate and product at any of the sites. At Yallaroi there was a significant crop biomass response to applied P in both the 30 and 40 cm row spacing’s. The response to liquid P only differed at the highest application rate. Crop biomass in the 30 cm row spacing was always greater than in the 40 cm row spacing. For grain yield there was no significant response to P for either liquid or granular product. Grain yields at the 40 cm row spacing were significantly lower than the 30 cm spacing by an average 0.5 t/ha at all P rates.

At Gilgandra in 2009 there was a strong P response in terms of both crop biomass and grain yield. There was little difference in the P response for the different row spacing’s although there did appear to be a greater response to the liquid P at the higher rate. Grain yields for the 40 cm row spacing with granular P were always lower than those from 30 cm row spacing

Trials showed little evidence of row spacing by phosphorus rate interactions. From the research to date there appears to be no reason to change phosphorus fertiliser recommendations based on row spacing or formulation choice in the northern grain region.

References:

McBeath TM, et al (2007) Predicting the response of wheat (Triticum aestivum L.) to liquid and granular P fertilisers in Australian soils. Aust. J. Soil Res. 45, 448–458.

Holloway RE, et al (2001) Improving fertiliser efficiency on calcareous and alkaline soils with fluid sources of P, N and Zn. Plant and Soil 236, 209–219.

Contact details

Dr. Guy McMullen, I&I NSW Tamworth, guy.mcmullen@industry.nsw.gov.au 02 6763 1100.

GRDC Project Code: NGA00002: Validation,

Was this page helpful?

YOUR FEEDBACK