Adjuvants and spray quality

| Date: 14 Feb 2009

• Adjuvants change the physical properties of spray solutions.

• Most commonly used non-ionic surfactant type adjuvants will increase drift potential.

• Where possible they should be replaced with drift reducing adjuvants such as some lecithin or other oil-based products.

Jorg Kitt, Business Manager Nufarm , Application Specialist Croplands, Adelaide, South Australia

The drift of pesticides away from the target area can cause expensive damage. Much progress has been made over the last years to minimise this risk with the use of air induction nozzles and coarser spray qualities.

Spray quality is the result of interactions between nozzle type, pressure and spray liquid. Surprisingly little emphasis is paid to the nature of the spray liquid itself. Data on spray quality is usually obtained by using water when in fact spray liquids contain agrochemicals with inert surfactant systems, and frequently, added adjuvants. Those components change the physical properties of water significantly.

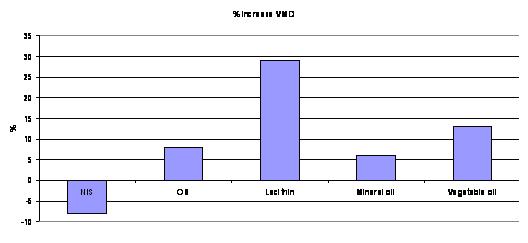

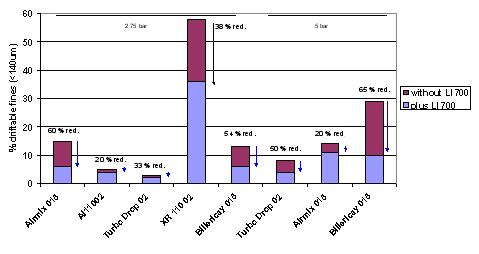

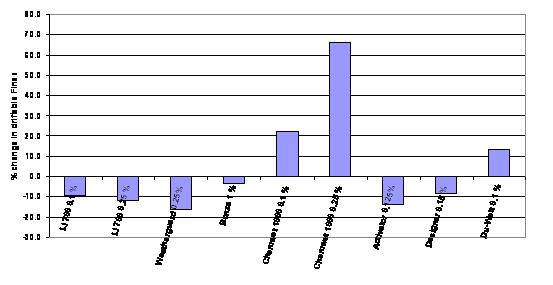

The impact of adjuvants is not constant and may vary with concentration, nozzle type and pressure (Figure 1). Many adjuvants such as non-ionic surfactants will usually lower the dynamic surface tension and generally increase the amount of small driftable fines. (Figures 1 & 3) In contrast, adjuvants containing lecithin or other type of oils will usually decrease the amount of driftable fines (Figures 1, 2 & 3).

However, because of the great variety of adjuvants on the market these general statements need to be treated with caution. Manufacturers of adjuvants often mask the chemical composition by loose terminology. To make it even more difficult, the quality and contents of supposed similar or identical adjuvants can vary greatly and influence the expected outcome. Only few adjuvants have a comprehensive data package to back up claims. Consequently, with the lack of reliable data, it is not easy for the end user to make an informed decision.

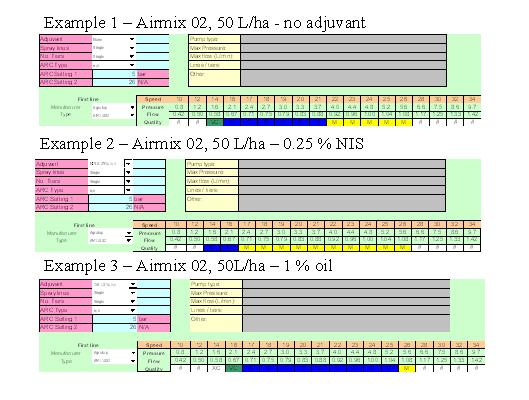

Control of droplet size is mainly achieved by selection of appropriate nozzles. However, adjuvants can alter spray quality significantly (Figure 4) and should be an integrated part of droplet management. Most commonly used non-ionic surfactant type adjuvants will increase drift potential. Where possible they should be replaced with properly researched, drift reducing adjuvants such as some lecithin or other oil-based products. Adjuvants should be part of the solution rather than being part of the problem.

Contact details

Jorg Kitt

Ph: 08 8359 9323

Fx: 08 8349 6175

Mb: 0429 939 403

Email: jorg.kitt@au.nufarm.com

Figure 1: Percent change of VMD when adjuvants are added to water. Summarized average values for Flat Fan nozzles from: “Review: influence of agricultural adjuvants on droplet spectra’ P. Spanoghe et al., Pest Manag Sci 63:4-16 (2007).

Figure 2: Reduction of driftable fines using a glyphosate formulation with a lecithin-based adjuvant. The Centre for Pesticide Application, Gatton 2006

Figure 3: The effect of different adjuvants on spray quality of an Airmix 01 - Percent change of driftable fines compared to water alone. The Centre for Pesticide Application, Gatton 2007

Figure 4: Impact of Adjuvants on Spray quality. Data from Nufarm droplet calculator

Was this page helpful?

YOUR FEEDBACK