STRIPE RUST MANAGEMENT - PREVENTION IS GENERALLY BEST

| Date: 14 Jul 2008

Take home message

· Early or preventative foliar sprays, applied from GS32 onwards on moderately susceptible varieties, have provided the best returns in northern trials over the last three years

· High grain prices and low fungicide costs mean breakeven yield benefits required are often only 1-2%

· Application can be the major cost of treatment

· Consider timing when stripe rust in area but not yet in crop or in tank mixture with a late herbicide, near GS32, to eliminate extra application cost

· If not preventative, need to ensure response is very rapid for most economic stripe rust management

· A second spray may still be necessary in high disease seasons

Background

Historically, fungicide recommendations for stripe rust management have been based on disease threshold levels on specific leaves. The approach helped to ensure fungicides were not applied until stripe rust was established and confirmed in the crop. This was a sensible strategy given high fungicide costs, low grain prices and the need for higher levels of yield benefit to generate economic returns. The downsides were the cost and impracticality of frequent monitoring combined with the rapid loss of yield potential if spraying was delayed.

Recent northern evaluation by QDPI&F, NSW DPI and NGA has confirmed that the most effective management of stripe rust will be achieved by spraying at or just prior to disease becoming evident in a crop. These results also support recent southern NSW management strategies that promote the use of a preventative strategy for management in varieties with stripe rust resistance ratings of 1-5.

So what has changed in recent years?

· Improved knowledge of the critical importance of application timing

· Fungicide prices have decreased dramatically

· Grain prices have increased

What are realistic yield benefit expectations?

The information below is a summary of the most recent independent northern regional data. Although it does not claim to cover all scenarios, it can help provide some framework for spray decisions.

Table 1: Yield benefits obtained from a single early foliar spray

|

Year

|

Organisation

|

Location

|

Variety (resistance rating)

|

% yield benefit

|

Actual benefit

kg/ha

|

|

2005

|

NSW DPI

|

Tamworth

|

BaxterA (4)

|

29*

|

-

|

|

2006

|

QDPI&F

|

Gatton

|

Baxter (4)

|

7

|

219

|

|

Warwick

|

PetrieA (3)

|

6

|

182

|

||

|

Warwick

|

Baxter (4)

|

4

|

139

|

||

|

Warwick

|

Baxter (4)

|

-1

|

-19

|

||

|

NGA

|

Bellata

|

Clearfield JNZA (4)

|

5

|

118

|

|

|

Bellata

|

Baxter (4)

|

11

|

223

|

||

|

2007

|

QDPI&F

|

Warwick

|

LangA (5)

|

5

|

185

|

|

Warwick

|

EGA WylieA (4)

|

13

|

490

|

||

|

Warwick

|

Petrie (3)

|

12

|

365

|

||

|

Gatton

|

Lang (5)

|

4

|

190

|

||

|

Gatton

|

EGA Wylie (4)

|

13

|

585

|

||

|

Gatton

|

Petrie (3)

|

11

|

415

|

||

|

|

|

|

Average

|

7

|

258

|

* Trial in a shadehouse with high disease pressure and extended grain fill period (not included in average)

NB 3 trials on H45 (1) have shown an average 197% yield benefit and 2182 kg/ha actual benefit

· Varietal resistance ratings are critical. Massive benefits on rating 1 (very susceptible) but much more modest on ratings 3-5 (moderately susceptible)

· Majority of ‘at risk’ varieties in north are rating 4-5

· Benefits only averaging ~7% but under generally lower disease pressure

· Rating 4 losses may go as high 30% under more favourable conditions

· No clear product rate response in most situations

The economics of management

The tables below identify the % yield benefit required to generate a 100% return on investment ie $2 return for every $1 invested.

Table 2: % yield benefit required (high fungicide costs, separate application)

|

Grain price $/t

|

Crop yield kg/ha

|

||||

|

1000

|

2000

|

3000

|

4000

|

5000

|

|

|

100

|

70

|

35

|

23

|

18

|

14

|

|

200

|

35

|

18

|

12

|

9

|

7

|

|

350

|

20

|

10

|

7

|

5

|

4

|

Shaded cells are where a % yield benefit less than 6% is required.

Assumptions: fungicide cost $20/ha, application cost $15/ha

Table 3: % yield benefit required (current fungicide costs, separate application)

|

Grain price $/t

|

Crop yield kg/ha

|

||||

|

1000

|

2000

|

3000

|

4000

|

5000

|

|

|

100

|

46

|

23

|

15

|

12

|

9

|

|

200

|

23

|

12

|

8

|

6

|

5

|

|

350

|

13

|

7

|

4

|

3

|

3

|

Shaded cells are where a % yield benefit less than 6% is required.

Assumptions: fungicide cost $8/ha, application cost $15/ha

Table 4: % yield benefit required (current fungicide costs but no extra application cost)

|

Grain price $/t

|

Crop yield kg/ha

|

||||

|

1000

|

2000

|

3000

|

4000

|

5000

|

|

|

100

|

16

|

8

|

5

|

4

|

3

|

|

200

|

8

|

4

|

3

|

2

|

2

|

|

350

|

5

|

2

|

2

|

1

|

1

|

Shaded cells are where a % yield benefit less than 6% is required.

Assumptions: fungicide cost $8/ha, application cost $0/ha

Assuming a yield loss of 7% is a reasonable (if moderately conservative) benchmark for stripe rust losses in rating 4-5 varieties:

· Table 2 highlights that at $20/ha fungicide prices you would still require yield potentials of >3t/ha to be confident of generating useful returns

· Table 3 highlights that with $8/ha fungicide prices, crops down to 2 t/ha may be economic for management and higher yield potential crops even if the grain price dropped to $200/t

· Table 4 highlights that if fungicides can be incorporated with another timely application eg a late herbicide spray, which in theory carries the application cost, the level of benefit required is small even if grain prices dropped dramatically or yield potentials are low

Preventative may be best but what is the cost if you get it wrong?

In simple terms, the cost of getting it wrong is the cost of the product plus application eg seed treatment ~ $10/ha including application, foliar fungicide ~$6-8/ha not including application. In 2007 however NGA ‘got it wrong’ over seven trials across northern NSW.

NGA used the variety Lang (rated as moderately susceptible, rating of 5) to compare the most practical stripe rust management strategies.

Table 5: Strategies evaluated

|

|

Strategy

|

At planting

|

Foliar timing & rate

|

|

No treatment

|

Untreated

|

-

|

-

|

|

Foliar fungicide only

|

Early foliar (low rate)

|

-

|

T1 low

|

|

Late foliar (low rate)

|

-

|

T2 low

|

|

|

Late foliar (high rate)

|

-

|

T2 high

|

|

|

Two sprays (low rate)

|

-

|

T1 low + T2 low

|

|

|

At planting +/- foliar fungicide

|

At planting

|

ü

|

-

|

|

At planting + early foliar (low rate)

|

ü

|

T1 low

|

|

|

At planting + late foliar (low rate)

|

ü

|

T2 low

|

T1 was an application when stripe rust was in the local area, not yet found in crop and crop stage was GS32 or beyond (three sites at ~GS32, four sites at ~GS39-45)

T2 was an application ~two weeks after T1

Table 6: Products and rates

|

Strategy

|

Product

|

Rate

|

|

At planting

|

Jockey®

|

300 mL/100 kg seed

|

|

Foliar (low rate)

|

Folicur®

|

145 mL/ha

|

|

Foliar (high rate)

|

Folicur®

|

290 mL/ha

|

The intention was to establish sites under a wide range of conditions and compare seed treatment protection with:

- foliar application shortly before expected disease incidence and

- foliar application applied approximately two weeks later

By mid August it was clear that crop condition and potential in six of the seven trials would not warrant any commercial consideration of stripe rust management. Treatments were however implemented as per protocol.

What did we find?

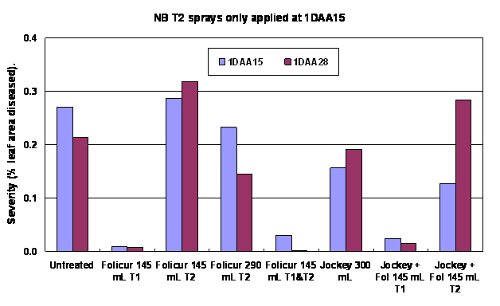

Very low stripe rust pressure generally occurred across northern NSW. This is indicated in Figure 1 by the average level of leaf area diseased (covered in pustules) being below 0.5%. No individual site recorded a level of stripe rust that exceeded 1% leaf area at any assessment.

NB 1DAA15 = 15 days after 1st application timing

Figure 1: Stripe rust control (average of all 7 sites)

· Stripe rust severity was very low at all sites

· Stripe rust however was still found at every trial site. This highlights the widespread nature of the disease and the regional risk when disease conducive climatic conditions occur

· Early (preventative) foliar application at T1 provided the most effective control

· Jockey alone provided only ~50% suppression at 1DAA15 (~11-14 weeks after planting)

· Poor performance by T2 application under these moisture stressed conditions

Grain yield

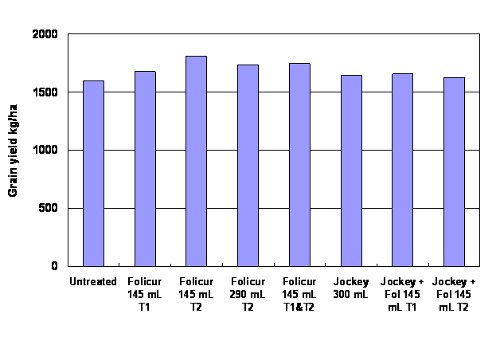

With very low disease levels and moderate to extreme soil moisture stress at most sites, it was not surprising that there were no significant differences in yield at any site. Six of the seven sites produced average yields of 1.6 t/ha or less with two sites only averaging 0.7 t/ha. Figure 2 below shows the overall average yields.

Figure 2: Yield results

· Across the seven sites, all treatments still averaged higher yield than the untreated (although with best apparent advantage to T2 sprays!)

· The average advantage over all fungicide treatments was 105 kg/ha (~7%)

· However, with such low disease pressure, clearly little of any apparent yield advantage can be attributed to stripe rust control

· 23 of 28 foliar alone treatments, across all sites, resulted in higher yields than the untreated control

Commercial outcome

Conditions in 2007 may represent close to a worst case scenario:

- Low yield potential crops suffering from moderate to severe moisture stress

- Very low stripe rust levels at all sites

- Brief period of disease duration

At grain prices of $350/t an average net benefit of $11/ha was still generated across all treatments. NB with grain prices of $200/t there would have been a net cost of $5/ha.

Key stripe rust management options

|

Strategy

|

Advantages

|

Disadvantages

|

|

Resistant variety

|

|

|

|

‘At planting’

|

|

|

|

Foliar preventative (after GS32)

|

|

|

|

Foliar reactive

|

|

|

Conclusions

Crop production is all about managing risk. With stripe rust management in the north, a body of recent data now exists that:

- Broadly identifies the level of likely yield loss

- Confirms the benefit of foliar application before or in the early stages of disease development

- Even provides some information on what to expect if the disease fails to develop

Certainly all preventative treatments are an insurance policy, but for stripe rust management the premiums are now low and the likelihood of a ‘payback’ is high at current grain prices.

Acknowledgements

Thanks to the growers and consultants involved in this trial work and to Bayer CropScience for the provision of fungicides for trials. Also thanks to Peter Wilkinson QDPI&F and Steven Simpfendorfer NSW DPI for their valuable contribution and input.

Contact details

Richard Daniel

Northern Grower Alliance

Ph: (07) 4698 7983

Email: richard.daniel@nga.org.au

A Varieties displaying this symbol beside them are protected under the Plant Breeders Rights Act 1994.

® Registered trademark

Was this page helpful?

YOUR FEEDBACK

To protect your privacy, please do not include contact information in your feedback. If you would like

a response, please contact us.